In today's dynamic and evolving world, innovation is inherent in every industry. This is no different for industry, where new technologies and solutions are constantly emerging to improve the efficiency and quality of production. One area where a lot of innovation is taking place is industrial connectors. With the changes that are being made, it is possible to achieve better performance, greater reliability and cost optimization.

Connectors in industrial technology

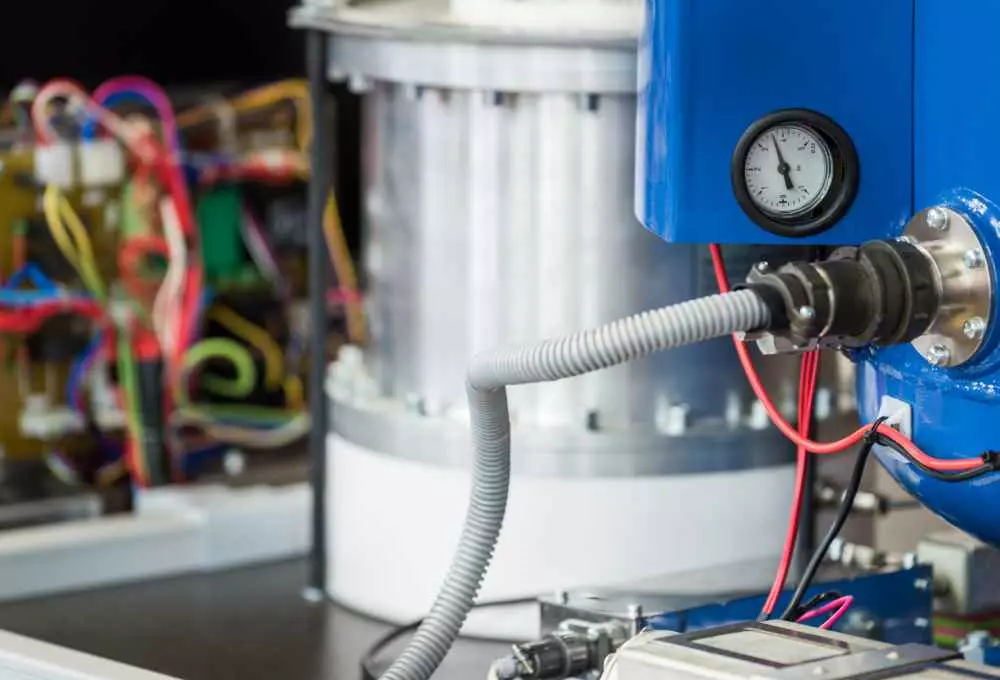

Industrial connectors are an essential component in many areas of industrial technology. They are used to connect various system components, such as pipes, cables, cabins, enclosures or control panels. The design principles of connectors vary and depend on the type of application, but one of the main requirements is to provide a durable and reliable connection. This is why innovation in industrial connectors is so important.

Modern materials

One of the key innovations in industrial connectors is the use of modern materials. Traditionally used steel or copper connectors are increasingly being replaced by connectors made of high-quality plastics. Such materials are characterized by lightness, strength, corrosion resistance and are resistant to various atmospheric agents. As a result, connectors made of modern materials are more durable and reliable.

A very important aspect of modern materials is also the ease of installation. Industrial connectors made of plastic are usually lighter than traditional steel or copper connectors, which makes them easier to transport and install. In addition, they can be used in applications where weight is a key factor, such as in the aerospace and automotive industries.

Connectors with smart features

Another innovation in the field of industrial connectors is connectors with smart functions. Using sensors, microprocessors and communication technologies, connectors can monitor various operating parameters, such as temperature, humidity or voltage. This information is transmitted to the control system and allows a quick response in the event of a failure or malfunction. In this way, serious technical problems can be avoided and the reliability of the entire system can be increased.

In addition, connectors with smart functions can also be programmed, making it possible to customize their operation. For example, connectors can automatically regulate the flow of substances, optimize energy consumption or provide information on material consumption. Such innovations allow optimization of production processes and improved efficiency of operations.

Safety and reliability

Last but not least, industrial connector innovations enhance safety and reliability. Connectors equipped with special safety mechanisms, such as mechanical interlocks or alarm systems, allow minimizing the risk of failure. In addition, modern connectors are designed with the latest safety standards in mind, which translates into greater protection for workers and optimal operation of the entire system.

All in all, innovations in industrial connectors bring many benefits to manufacturers and users. Modern materials, connectors with intelligent functions, and increased safety and reliability make production processes more efficient, and the associated costs are optimized. It is therefore worth following developments in this field and taking advantage of the latest technologies to be competitive in the industrial market.

Add comment