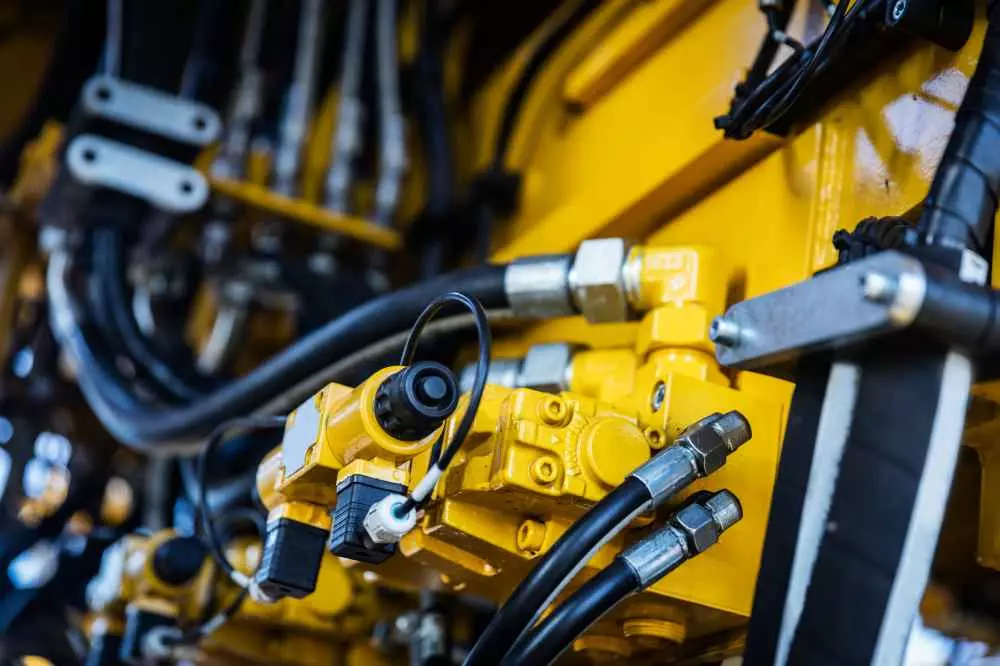

Customized solutions for industrial connectors

Industrial connectors are an extremely important component in many industrial sectors. When properly selected and customized, they can significantly affect the performance and efficiency of systems. In this article, we will present solutions to meet the requirements of each industry.

What are the key factors influencing the choice of industrial connectors?

When choosing industrial connectors, there are many factors to consider. The most important of these are:

1. Type of application: Connectors vary depending on the type of application for which they are to be used. For example, the automotive industry requires high-strength connectors that can withstand extreme temperatures and vibration.

2. Operating environment: Connectors should be adapted to the environment in which they will operate. When operating in extreme conditions, such as high humidity or dust, it is important to use connectors that are protected from the elements.

3. Technical requirements: The customer should specify its technical requirements for connectors. These may include conductivity efficiency or voltage data.

4. Ease of installation: Good connectors should be easy and convenient to install, which speeds up the installation process and reduces the risk of errors.

How to customize connectors?

1. Consultation with an expert: For intricate and specialized customer requirements, it is worthwhile to consult an expert or engineer who can help select the right connectors. Technical advice is key to achieving the optimal solution.

2. Material matching: Choosing the right materials is crucial. There are connectors available on the market made of different materials, such as aluminum, stainless steel, titanium or polymer. Choosing the right material depends on the application requirements, production costs and the expected life of the connector.

3. Testing: Before the connectors are put into production, the customer may choose to conduct tests to verify that the connectors meet the requirements. Testing will identify any problems and make any necessary modifications.

4. Personalization: Many manufacturers offer the option of personalizing connectors, for example by engraving the customer's logo on the housing. This is an excellent way to strengthen the brand and stand out in the market.

What are the benefits of customized industrial connector solutions?

Customized connectors bring many benefits, such as:

1. Cost optimization: Good customized connectors minimize production and system maintenance costs, which translates into savings for the customer.

2. Increased productivity: Matching industrial connectors to application requirements allows systems to be more efficient. Properly matched connectors guarantee stable connections, eliminating potential downtime and failures.

3. Longer service life: Properly selected connectors are more durable and resistant to mechanical damage or corrosion. This translates into longer system life and lower repair and replacement costs.

4. Customized approach: Tailored solutions allow customers to get a product that perfectly meets their needs. This also gives confidence that the system will perform as expected.

In summary, choosing the right industrial connectors and customizing them is important for the efficiency and performance of systems. That's why it's a good idea to consult an expert and use suppliers that offer personalized solutions. This way you can be sure that the connectors will work reliably for a long time and that the systems will meet all requirements.

Add comment