Introduction

Nowadays, fiber optic and network cable technology is an integral part of our lives. Without cables, it would be impossible to transfer data, access the Internet or even make a phone call. A well-executed cable installation is crucial to maintain the quality of connections and ensure reliable communication. In this article, we will introduce the most popular cable installation products that will make the installation process easier for you and ensure the durability and safety of your connections.

Key products for cable assembly

1. Cable connectors are some of the most important components of cable assembly. Connectors allow you to securely and permanently connect two or more cables. It is important to choose the right type of connector, the type of which depends on the type of cable and its purpose. Remember that good quality connectors are reliable and do not adversely affect the signal throughput.

2. Reduction inserts used when you want to connect cables of different diameters. Reducing inserts ensure an exact fit of cables and minimize the risk of signal loss or interference. When choosing reduction inserts, pay attention to the compatibility with a particular cable model and their workmanship quality.

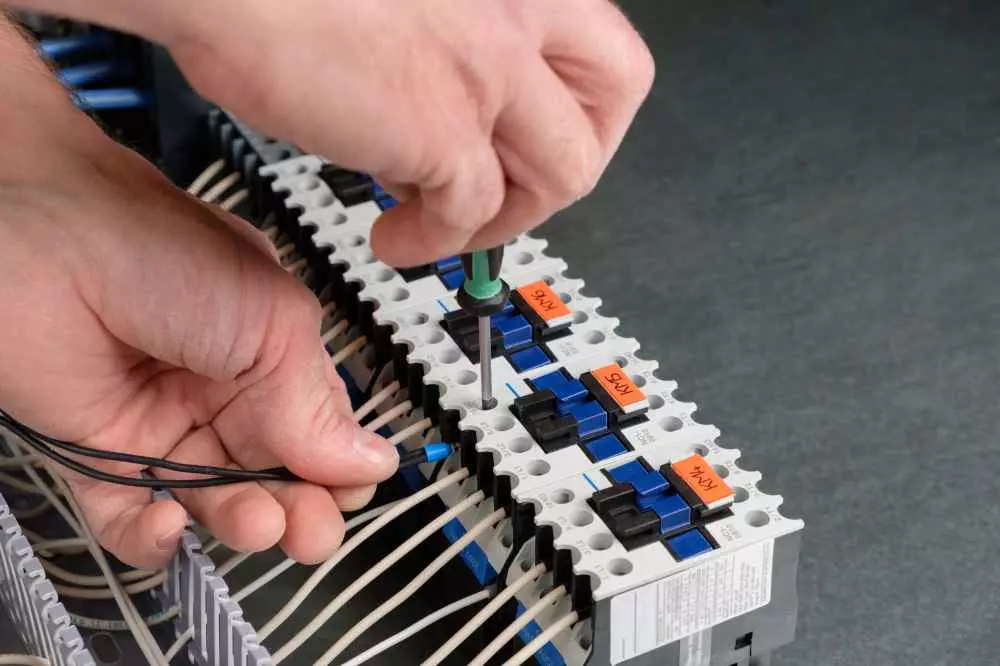

3. Installation tools To carry out professional cable installation, it is necessary to have the right tools. A basic set of cable assembly tools should include: twisting pliers, cable scissors, cable tester, crimper, assembly clamps and more. Remember that using quality tools translates into the quality of the completed installation and trouble-free connections.

4. Insulating tapes key when you want to protect cable connections from moisture, temperature or mechanical damage. Insulation tapes are also helpful for grouping cables and keeping the installation tidy. When choosing insulating tapes, make sure they are durable, weatherproof and have adequate adhesive strength.

Cable assembly process

Cable assembly requires precision, accuracy and skill. Before you begin installation, make sure you have all the necessary products and tools. The following is the general cable installation process:

1. Cable preparation if you are using cables with a special braid, carefully remove the protective layer. Then thoroughly clean the ends of the cables, removing any dirt and insulation residue.

2. Twisting the cables Depending on the type of installation and needs, we may choose to twist the cables. To do this, we use twisting pliers, which will precisely perform this task. It is important to maintain the right amount of rotation of the twisted cable to ensure proper operation of the connection.

3. Connectors and reduction inserts Now it is time to place connectors or reduction inserts on the cable ends. Make sure that the connectors are properly fitted to the cable and tighten them carefully so that there is no slack or loosening of the connection.

4. Insulation to protect the connections and eliminate the risk of mechanical damage or moisture, use insulating tapes. Carefully wrap the connection site with tape, making sure it is well adhered and durable.

5. Testing Finally, perform tests to check the correctness of the connection and signal quality. Use a cable tester to make sure the connection is made correctly and there is no interference or signal loss.

Summary

Professional cable installation is key to ensuring reliable connections and maintaining high signal quality. When choosing cable assembly products, pay attention to their quality, compatibility with the type of cable and the necessary tools. Also remember to properly insulate the connections to protect them from the elements. Follow the proper installation process to ensure the robustness and durability of the installation. Be a professional copywriter and use the tools available to provide valuable information to your readers.

Add comment